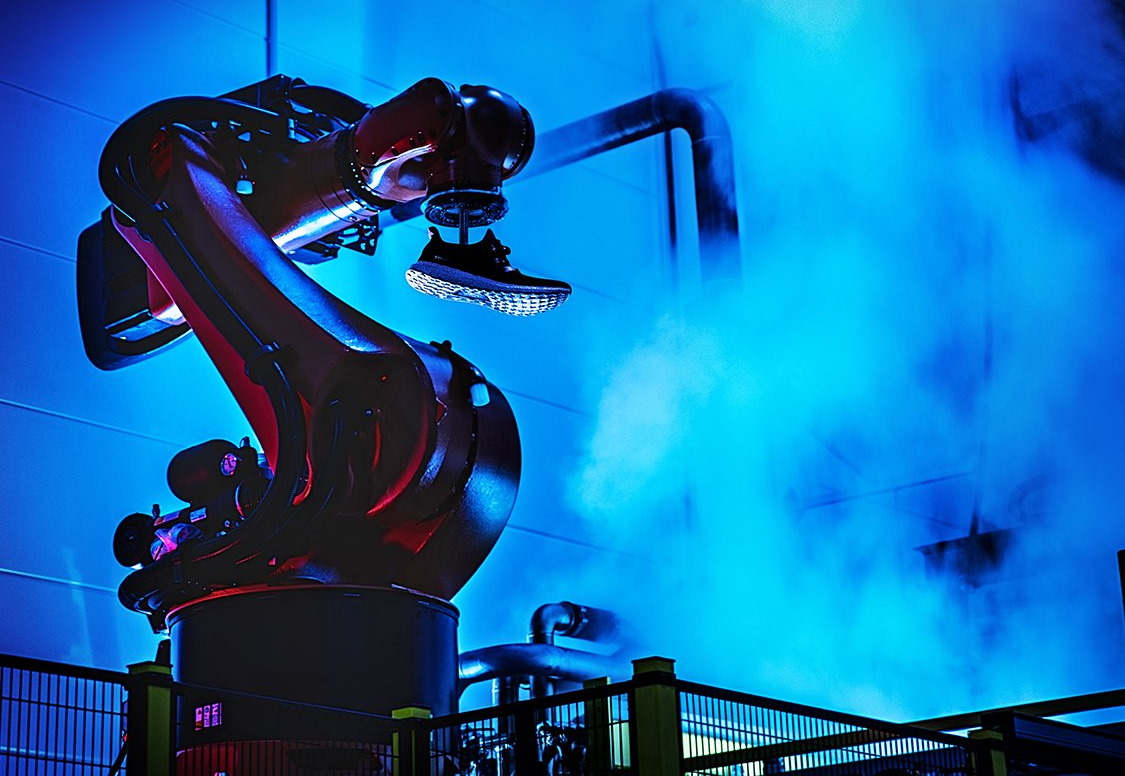

In a world where agility and speed dictate success, the recent announcement from Adidas to wind down its robotic Speedfactories in Atlanta and Ansbach certainly raises eyebrows. Established to revolutionize the sneaker production process, these high-tech facilities were envisioned as a cornerstone-technology in the companys mission to modernize manufacturing. However, just two years after launching these experimentations, Adidas is opting to pivot, shedding light on the complex relationship between innovation and feasibility in todays fast-paced market.

The Genesis of Speedfactories

The launch of the Speedfactory concept in 2016 marked a new chapter for Adidas, aiming to decentralize production and decrease delivery times. The idea was not only to capitalize on the technology advancements but to shorten the supply chain by planting factories closer to key markets. Adidas CMO, Eric Liedtke, emphasized this move during an interview, stating that instead of relying solely on overseas production, they wanted localized micro-factories to get products directly to consumers. But was the vision too ambitious when measured against the complexities of robotics?

Challenges in Robotic Manufacturing

- Technological Limitations: The complexities of setting up and reconfiguring robotic systems cannot be understated. These facilities are equipped with intricate technology like robotic arms and computer vision systems, but managing such technology is far more challenging than initially anticipated.

- Human-Machine Interaction: Unlike the traditional human workforce that can be trained to adapt, robotic systems often require specialized knowledge to operatethis makes quick pivots less feasible.

- Cost and Complexity: As seen in Adidas experience, the economic proposition of robotic manufacturing can often fall short when facing practical execution issues, leading to reconsiderations of operational strategies.

Examining the Future of Manufacturing

In light of these challenges, Adidas plans to redirect its focus by employing the technology and learnings from the Speedfactories within its established Asian factories starting next year. While this might appear as a retreat, it is also a recognition of the need to integrate advanced methodologies within traditional frameworks, potentially leading to manufacturing efficiencies without the burden of running wholly robotic facilities.

Lessons for the Industry

The experience of Adidas with the Speedfactories offers key insights for other companies navigating the intricate landscape of modern manufacturing.

- Embrace Flexibility: While automation presents numerous advantages, companies must ensure that their operational models can pivot quickly in response to unforeseen challenges.

- Invest in Sustainable Practices: The ability to adapt and repurpose existing technologies can often yield better results than committing wholly to untested innovations.

- Rethink Robotics Integration: The integration of robotics into traditional manufacturing should be viewed as a gradual process rather than a complete replacement of the existing workforce.

Conclusion: A Call to Adaptation

The closure of Speedfactories signals a need for reflection on what the future holds for automated manufacturing. While Adidas has chosen to step back from its approach, the lessons learned from this endeavor could become a blueprint for more successful integrations of technology in production. As players in the industry continue to learn from such experiments, it lays the groundwork for future innovations where efficiency and adaptability are not only expected but are the standard.

At **[fxis.ai](https://fxis.ai)**, we believe that such advancements are crucial for the future of AI, as they enable more comprehensive and effective solutions. Our team is continually exploring new methodologies to push the envelope in artificial intelligence, ensuring that our clients benefit from the latest technological innovations.

For more insights, updates, or to collaborate on AI development projects, stay connected with **[fxis.ai](https://fxis.ai)**.