If you’ve ever indulged in the luscious sweetness of a fresh raspberry, you know that the experience is truly delightful. However, the delicate art of picking these berries is not as straightforward as it seems. For years, the challenges faced by robots in accurately harvesting raspberries have limited the application of automation in this field. But thanks to innovative research from Switzerland, we may soon witness the culmination of advanced robotics and agricultural efficiency with the emergence of the Robo-Berry.

The Challenges of Raspberry Picking

Raspberry harvesting is an intricate process that requires a fine balance of strength and gentleness. The key lies in the ability to grip the berry without crushing it, detach it precisely from its receptacle, and do all of this quickly enough to meet the demands of a short harvesting season. Traditional robots struggle in this delicate operation due to a lack of tactile sensitivity and intuition that human hands possess – qualities honed through millions of years of evolution.

A Breakthrough: The Sensorized Raspberry

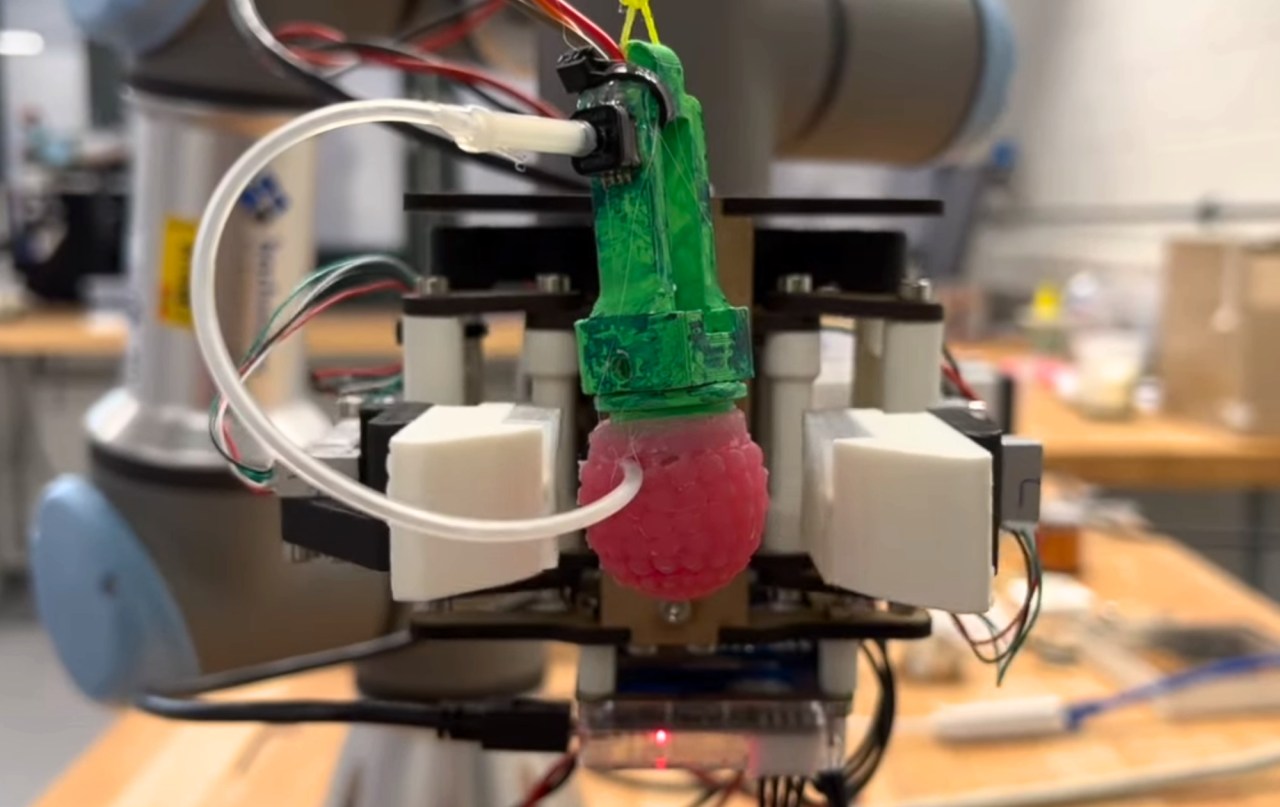

Enter Kai Junge, a PhD student at the École Polytechnique Fédérale de Lausanne (EPFL), and his groundbreaking work with the sensorized raspberry. This innovative replica, made from silicone and silicon, is designed to provide real-time feedback to the robotic harvesting systems. By mimicking the physical properties of a real raspberry, this artificial version serves as a training tool, helping robots learn how to pick faster, better, and more gently.

How Does It Work?

- Fluidic Sensors: The replica berry incorporates fluidic sensors that monitor the pressure exerted during gripping. This data helps adjust the robotic grip dynamically, preventing any crushing damage.

- Learning Capabilities: The feedback mechanisms allow the harvesting robot to adapt its technique based on the information received from the sensorized berry, essentially creating a form of communication between the robot and its target.

- Lab Testing: Rather than testing directly in the field, which would be cumbersome and costly, the research team uses the lab setup to refine their technology, tackling the complexities of detachment in a controlled environment.

Implications Beyond Raspberries

The pioneering work of Junge and his team not only opens doors for robotics in raspberry harvesting but also sets the stage for tackling other types of fruits and crops, such as tomatoes, grapes, and even apricots. By mastering the art of berry-picking, robotic capabilities could extend into various agricultural sectors, enhancing productivity and reducing waste.

The Future of Automated Agriculture

The findings will be presented at RobotSoft in April, signaling an exciting moment for both robotics and agriculture. As we look towards the future, the integration of advanced technology in our food systems stands to transform the industry, making operations more efficient and sustainable.

Conclusion

The Robo-Berry exemplifies how robotics can learn from nature to drive innovation and efficiency in agriculture. By leveraging intelligent systems that can adapt and respond to the intricacies of fruit picking, we are led towards a future where technology harmoniously works alongside nature to bring us the best of both worlds. At **[fxis.ai](https://fxis.ai)**, we believe that such advancements are crucial for the future of AI, as they enable more comprehensive and effective solutions. Our team is continually exploring new methodologies to push the envelope in artificial intelligence, ensuring that our clients benefit from the latest technological innovations.

For more insights, updates, or to collaborate on AI development projects, stay connected with **[fxis.ai](https://fxis.ai)**.