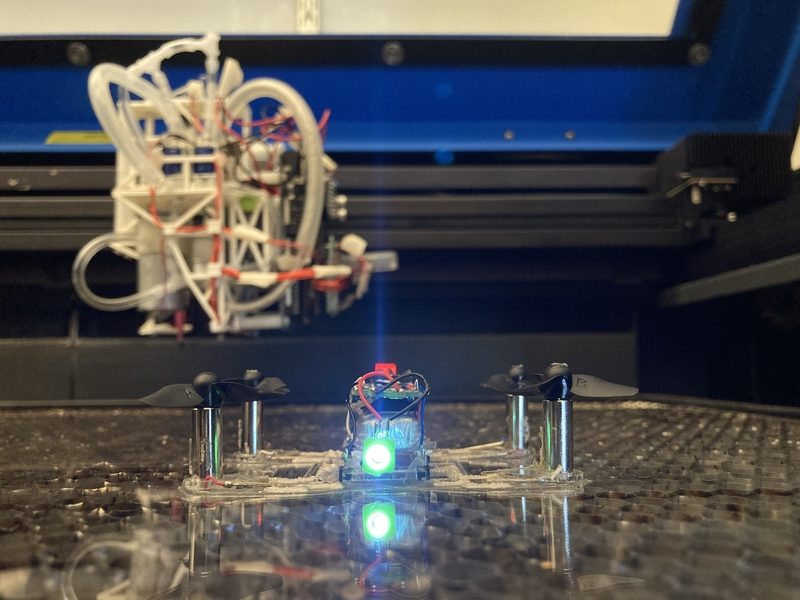

The field of additive manufacturing has witnessed a remarkable evolution over the years. Despite its potential to produce intricately designed components, the need for post-printing assembly often detracts from its appeal. Enter MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) with an ambitious new initiative: **LaserFactory**. This innovative project aims to create a comprehensive platform for 3D printing that not only fabricates parts but also assembles them, reducing the reliance on external assembly mechanisms.

What is LaserFactory?

LaserFactory represents a groundbreaking advance in 3D manufacturing technology. This system combines both software and hardware to revolutionize the way we think about creating functional machines, including robotics and drones. By automating the entire process—from design to assembly—LaserFactory can transform the complex world of fabrication into a straightforward task that even non-experts can manage.

A User-Friendly Approach to Design

Imagine wanting to build your own drone. Under the LaserFactory model, users start with a simple interface that allows them to select components from a vast library. They can then draw circuit traces onto the design using intuitive 2D editing software. This innovative design flow enables users to visualize their final products, ensuring that electrical connections are correctly made before the printing process begins.

- Design Interface: An accessible environment for users to piece together components and create personalized designs.

- Automated Circuit Assembly: The integration of circuitry directly into the printed device eliminates tedious manual assembly.

- Prototype Visualization: A feature that enables users to preview their creations to minimize errors before production.

The Multifaceted Nature of LaserFactory

What sets LaserFactory apart from existing 3D printing solutions is its unique capability to combine various manufacturing processes in one cohesive system. Traditionally, printing and assembly necessitated various tools and equipment, leading to increased costs and accessibility barriers.

PhD student and lead author Martin Nisser expressed that, “Making fabrication inexpensive, fast, and accessible to a layman remains a challenge.” To address this, LaserFactory leverages common manufacturing tools such as 3D printers and laser cutters, creating an all-in-one solution that promises to broaden the reach of additive manufacturing capabilities.

The Future of Additive Manufacturing

Although MIT plans to present a more refined version of LaserFactory by May, the current iteration has already sparked interest and intrigue within the tech community. The scalability of this system could significantly impact not just hobbyists but also industries seeking agile production methods. From rapid prototyping to educational applications, the potential use cases are vast and compelling.

Conclusion

As we look ahead, the integration of automated systems like LaserFactory could redefine the boundaries of what’s possible with 3D printing. By merging accessibility with high functionality, MIT’s initiative stands to empower creators, inventors, and engineers alike in creating sophisticated devices right at their fingertips.

At fxis.ai, we believe that such advancements are crucial for the future of AI, as they enable more comprehensive and effective solutions. Our team is continually exploring new methodologies to push the envelope in artificial intelligence, ensuring that our clients benefit from the latest technological innovations.

For more insights, updates, or to collaborate on AI development projects, stay connected with fxis.ai.