The world of gas turbine technology is fraught with challenges, particularly when it comes to maintenance and inspections. As engineers grapple with the intense heat and the incessant spinning of turbine blades, the traditional method of employing borescopes for inspection has proven to be cumbersome and limited. However, innovation is underway. Welcome to the future of turbine inspections brought forth by an exceptional team at the GE Global Research Center.

The Limitations of Traditional Inspection Methods

Traditionally, a borescope is lowered through a designated opening to inspect the inner workings of a gas turbine. While this method has been the standard for years, it faces significant drawbacks. Kori Macdonald, a robotics engineer at GE, eloquently describes the limitations: navigating the scope to different turbine points while maintaining proper orientation can become an exercise in frustration. Furthermore, once an issue is detected, the necessary repairs are not straightforward; shutting down the turbine, dismantling it, and conducting repairs can take hours—time when the turbine is out of commission.

Introducing ‘The Turbine Surgeon’

To tackle these challenges head-on, GE embarked on an ambitious project known as ‘The Turbine Surgeon.’ The team’s focus was clear—create small, flexible robots capable of moving between the turbine blades as they whirl, thereby enhancing visibility and addressing issues in real-time. This led to the development of impressive prototypes, one of which is the size of a PC card and features advanced components like high-resolution pivoting cameras and ultra-bright LED lights.

Innovative Robotics: Key Features

- Flexible Movement: Unlike traditional borescopes, these robots can move freely among the blades, providing engineers varied perspectives and insights into potential problems.

- On-the-Fly Repairs: The introduction of a repair module attached to the robot represents a significant leap forward—capable of applying repair material directly onto compromised coatings while still in operation.

- Intuitive Control: Operators can utilize software to maneuver these robots, offering control that enhances the efficiency of inspections and maintenance.

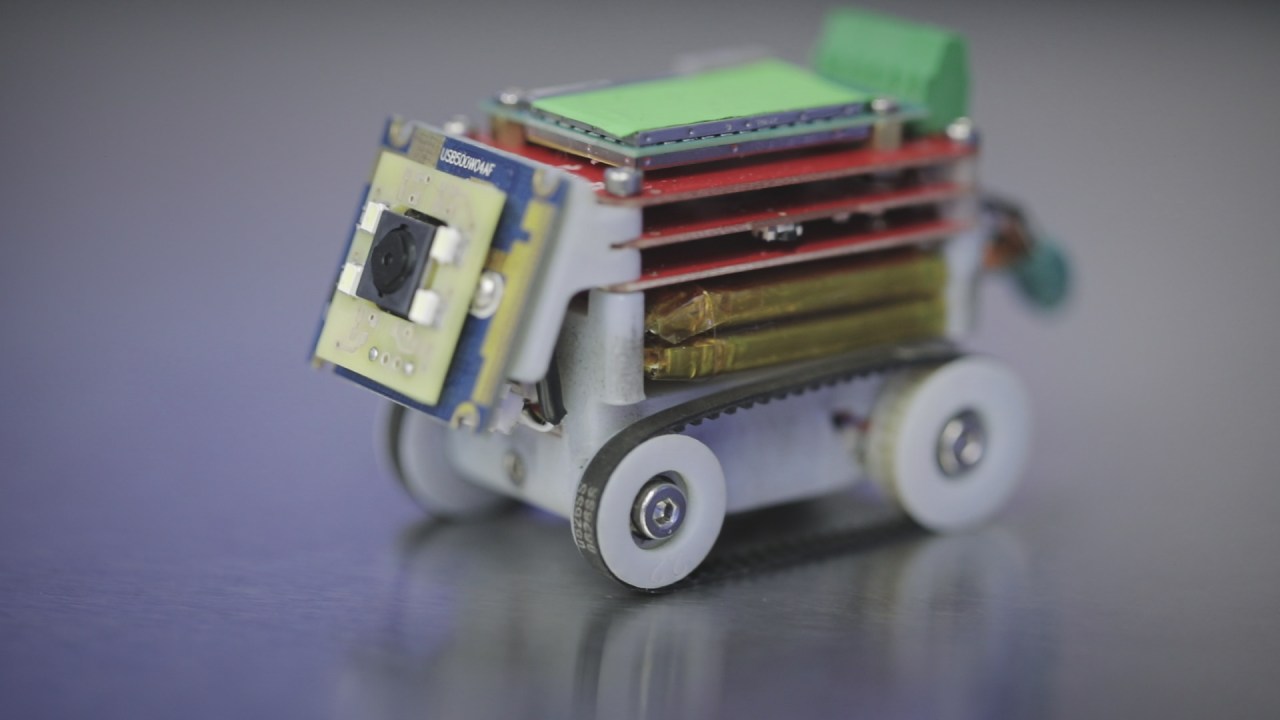

The Crawler: A Closer Look

Adding to the impressive suite of robots is ‘The Crawler,’ resembling a miniature truck with magnetic wheels that allow it to adhere to the turbine blades. This innovation enables the robot to perform inspections while physically moving across the blade surfaces. With application-driven controls via smartphones or laptops, operators can guide The Crawler deftly with a virtual joystick. This opens a realm of possibilities for additional attachments that accommodate various maintenance tasks.

A Fresh Perspective on Triage

What stands out in the initiative is GE’s commitment to reimagining the turbine inspection process. The introduction of a new approach has sparked innovative solutions that were previously overlooked. As Macdonald highlights, the proactive maintenance facilitated by these robots not only saves time but also mitigates further damage—akin to addressing a dental issue before it escalates into greater complications. Immediate interventions can lead to substantial long-term benefits.

Conclusion: The Future of Turbine Maintenance

The prototypes developed through ‘The Turbine Surgeon’ project not only illustrate creative engineering but also suggest a marked shift in how we approach gas turbine inspections. By blending robotics and intelligent software solutions, the future of turbine maintenance looks promising. As GE continues to refine these prototypes, the trajectory towards minimizing downtime and maximizing efficiency becomes increasingly attainable.

At fxis.ai, we believe that such advancements are crucial for the future of AI, as they enable more comprehensive and effective solutions. Our team is continually exploring new methodologies to push the envelope in artificial intelligence, ensuring that our clients benefit from the latest technological innovations.

For more insights, updates, or to collaborate on AI development projects, stay connected with fxis.ai.