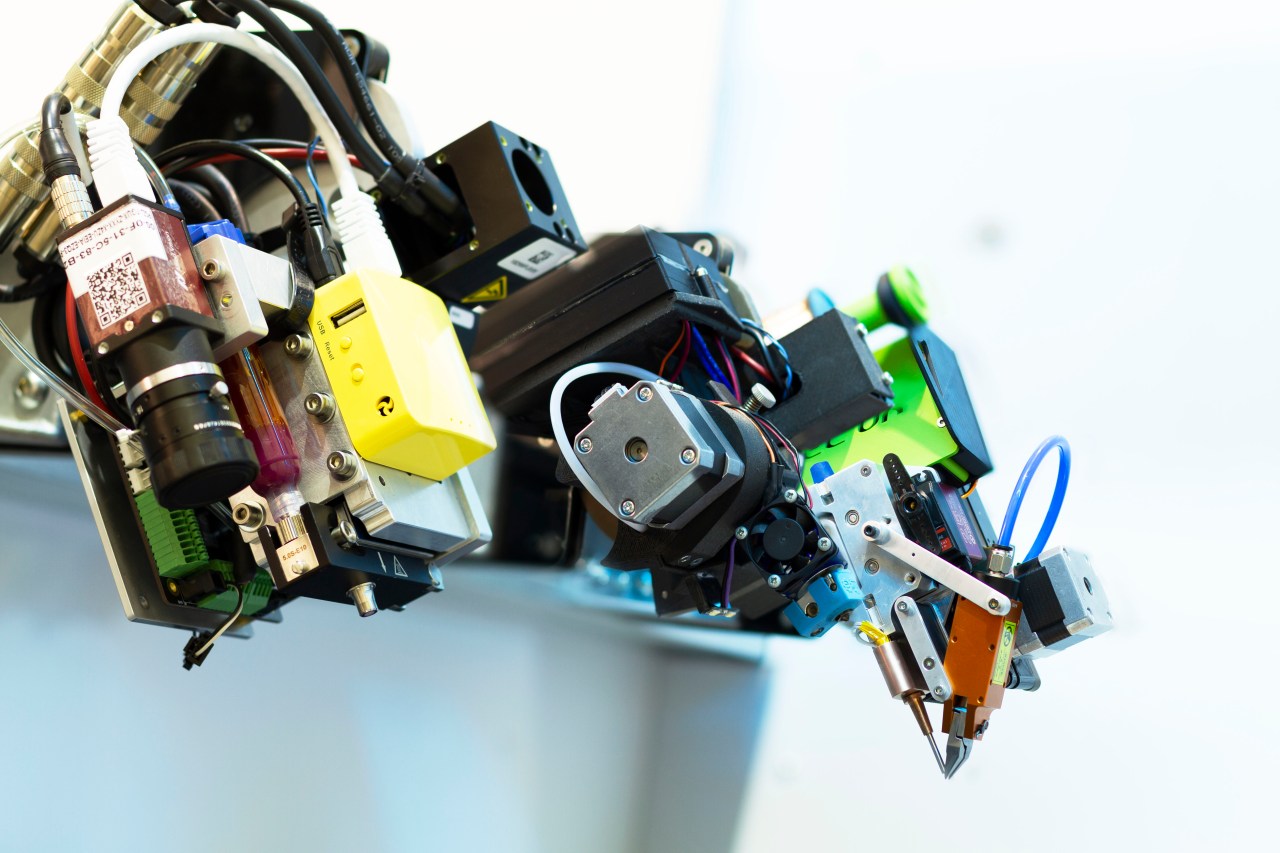

As industries grapple with the challenges of inefficiencies and rising labor costs, the integration of robotics into traditional manufacturing processes offers a compelling solution. One such pioneering company leading the charge is Q5D, a Bristol-based startup that aims to automate the production of wiring harnesses for electronics—an area that remains surprisingly labor-intensive despite technological advancements. Their vision? Transform the wiring production process from a manual endeavor into a streamlined, automated workflow that not only reduces costs but also minimizes human error.

The Complex World of Wiring Manufacturing

Wiring harness production, a critical aspect of electronic manufacturing, has long been performed by skilled human workers, which brings with it a host of challenges. Central to Q5D’s proposition is the notion that wiring assemblies, which are essential components in everything from aerospace applications to consumer electronics, often remain handmade due to their intricate design and the degree of accuracy required. The result? A bottleneck that can stymie production efficiency and elevate operational costs.

Meet Q5D

Founded in 2019 by Steve Bennington and Chris Elsworthy, Q5D is the culmination of their extensive experience in the tech space, including previous roles at Cella Energy and CEL-UK. It’s worth noting that Q5D is not operating in isolation; it is a joint venture between CEL-UK and M-Solv, both of which bring critical expertise in 3D printing and machine tools for electronics manufacturing to the table.

Q5D’s advancement in the realm of wiring automation has been further bolstered by their participation in HAX’s hardtech startup program. Recently, they secured a $2.7 million seed funding round led by Chrysalix Venture Capital, aimed at scaling their technology for broader distribution. This infusion of capital represents a significant vote of confidence from investors who understand the critical need for automated solutions in the manufacturing landscape.

The Broader Impact of Automation

With current clients ranging from aerospace giants such as Safran to cutting-edge firms like Oxford Space Systems, Q5D’s technology is already making waves. However, the company recognizes that its potential extends to the automotive and consumer electronics sectors as well. As Bennington highlights, “The way the world has made wiring for the last 80 years has to change.” This statement captures the essence of the industry—a call to action for manufacturers to embrace automation, especially in an era where electronic wiring systems are becoming increasingly complex.

- Efficiency Gains: By leveraging robotics, manufacturers can drastically cut down on time spent on wiring assembly.

- Cost-Effectiveness: Automating labor-intensive tasks can lower production costs significantly.

- Precision: Machines minimize the scope for human error, yielding higher quality products.

Looking Ahead: The Future of Wiring in Electronics

As technology evolves, so does wiring design and application. The electrification of transport systems and the growing technological functionality of everyday items necessitate a rethinking of manufacturing strategies. The vision for firms like Q5D is not merely incremental improvement but a wholesale transformation of an industry that has remained unchanged for too long.

This shift towards automation is not just about enhancing productivity; it’s about paving the way for a sustainable and efficient future in manufacturing. Such advancements are crucial for the future of AI, as they enable more comprehensive and effective solutions. Our team at fxis.ai is continually exploring new methodologies to push the envelope in artificial intelligence, ensuring that our clients benefit from the latest technological innovations.

Conclusion

In conclusion, Q5D’s endeavor to automate the wiring process is emblematic of a larger movement towards integrating robotics in traditional manufacturing sectors. By addressing the complexities involved in wiring production, Q5D is positioning itself as a forerunner in a field ripe for innovation. As industries continue to evolve, the need for automated solutions that enhance productivity and minimize error only grows stronger. For more insights, updates, or to collaborate on AI development projects, stay connected with fxis.ai.